- Home

- About us

- Products

- COMPOSITES MATERIAL

- —fibreglass & carbon

- —infusion consumables

- —sandwich panels

- —GlossLamix™ skin sheet

- —EcoLamix™ skin sheet

- —MaxFloat™ syntactic foam

- 3S INDUSTRIAL LIFTING

- —blade maintain platform

- —ladder hoist

- WEARABLE EXOSKELETON

- —PES-B back suit

- —PES-U upper Limb Suit

- —FIT-HV lumbar exo

- —FIT-U upper limb exo

- Contact us

Chopper Gun Roving - Glass fibre

Description

Chopper Gun Rovings, in a 2,400 or 3,000 tex format, are designed to use reinforcing silane couple sizing, and it provides superior process ability with low spring back in the tight radius area. It also provides with excellent anti-static and dispersion performance and fast wet-out. The product is compatible with polyester and vinylester resin systems.

The chopper gun roving is typically with a 17.5kg roll and stocks bulk of 840kg or 1,120kg per pallet.

Application

Compatible with polyester, vinyl ester resin system. Typical applications are swimming pool, bath tub, FRP boat and tank, plaster panels.

Process

Chopper gun process: The fibreglass roving are cut into smal strands by the chopper gun and sprayed with resin into mould surface. Manual rolling is necessary to eliminate air bubbles and enhance the resin impregnation.

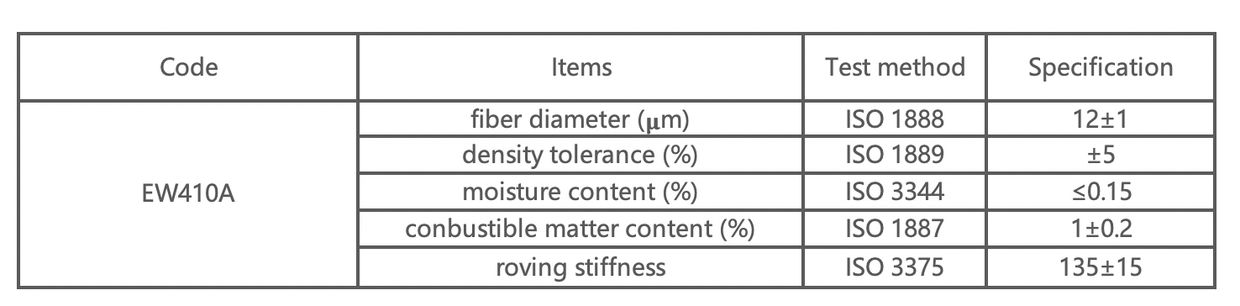

E-CGR

This website uses cookies

We use cookies to analyze website traffic and optimize your browsing experience. By accepting our use of cookies, your data will be aggregated with all other user data